In the quest to develop life-like materials to replace and repair human body parts, scientists face a formidable challenge: Real tissues are often both strong and stretchable and vary in shape and size.

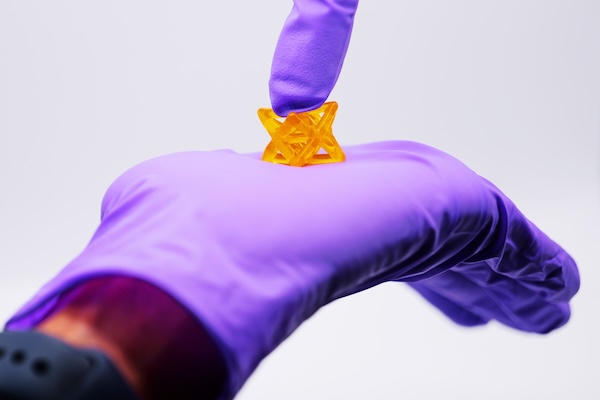

A CU Boulder-led team, in collaboration with researchers at the University of Pennsylvania, has taken a critical step toward cracking that code. They’ve developed a new way to 3D print material that is at once elastic enough to withstand a heart’s persistent beating, tough enough to endure the crushing load placed on joints, and easily shapeable to fit a patient’s unique defects.

Their breakthrough, described in the Aug. 2 edition of the journal Science, helps pave the way toward a new generation of biomaterials, from internal bandages that deliver drugs directly to the heart to cartilage patches and needle-free sutures.

“This is a simple 3D processing method that people could ultimately use in their own academic labs as well as in industry to improve the mechanical properties of materials for a wide variety of applications,” says first author Abhishek Dhand, a researcher in the Burdick Lab and doctoral candidate in the Department of Bioengineering at the University of Pennsylvania. “It solves a big problem for 3D printing.”

Read the full story by Lisa Marshall and Nicholas Goda on CU Boulder’s website

Jason Burdick is Bowman Endowed Professor in Chemical and Biological Engineering at the University of Colorado Boulder and Adjunct Professor in Bioengineering at Penn Engineering.