By Sophie Burkholder

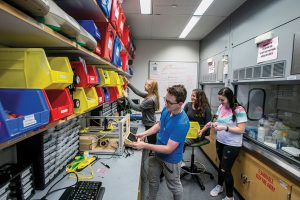

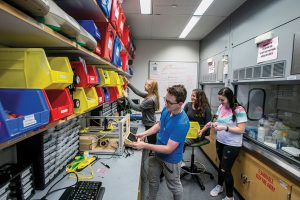

As technology and hands-on activities continue to become a larger part of education at all levels, a new movement of do-it-yourself projects is on the rise. Known as the “MakerSpace Movement,” the idea is that with the use of devices like 3-D printers, laser cutters, and simple circuitry materials, students, classes and communities can apply topics discussed in the classroom to real-life projects. Especially popular among STEM educators, the MakerSpace Movement is one that’s taken over labs in engineering schools around the country. Here at Penn, our own Stephenson Foundation Bioengineering Educational Lab and Bio-MakerSpace is equipped with all of the tools needed to bring student designs to fruition. In particular, the Stephenson Lab is the only lab on Penn’s campus that is open to all students and has both mechanical and electrical rapid prototyping equipment, as well as tools for biological and chemistry work.

As technology and hands-on activities continue to become a larger part of education at all levels, a new movement of do-it-yourself projects is on the rise. Known as the “MakerSpace Movement,” the idea is that with the use of devices like 3-D printers, laser cutters, and simple circuitry materials, students, classes and communities can apply topics discussed in the classroom to real-life projects. Especially popular among STEM educators, the MakerSpace Movement is one that’s taken over labs in engineering schools around the country. Here at Penn, our own Stephenson Foundation Bioengineering Educational Lab and Bio-MakerSpace is equipped with all of the tools needed to bring student designs to fruition. In particular, the Stephenson Lab is the only lab on Penn’s campus that is open to all students and has both mechanical and electrical rapid prototyping equipment, as well as tools for biological and chemistry work.

Though Penn helps to fund the lab’s operation, many of the technologies and materials used in the Stephenson Lab and Bio-MakerSpace to help students throughout different class and independent projects are actually relatively affordable. Sevile Mannickarottu, Director of the Educational Laboratories, recently presented a paper describing the innovations and opportunities available to students through the MakerSpace attributes of the lab.

The Stephenson Lab mostly looks to support bioengineering majors, particularly in their lab courses and seniors design projects, but also encourages students of all disciplines to use the space for whatever MakerSpace-inspired ideas they might have, whether it be fixing a bike or measuring EMG signals for use in a mechanical engineering design.

Believe it or not, however, some of the best parts of the Bio-MakerSpace can actually be purchased for a total of under $1500. Though that number is probably far beyond the individual budget of most students, it might be more affordable for a student club or dorm floor that receives additional funding from Penn. While the idea of building a MakerSpace from nothing might sound intimidating, the popularity of the movement actually helps to provide a wide range of technology and affordable options.

Believe it or not, however, some of the best parts of the Bio-MakerSpace can actually be purchased for a total of under $1500. Though that number is probably far beyond the individual budget of most students, it might be more affordable for a student club or dorm floor that receives additional funding from Penn. While the idea of building a MakerSpace from nothing might sound intimidating, the popularity of the movement actually helps to provide a wide range of technology and affordable options.

One of the hallmarks of the MakerSpace at the Stephenson Lab, and of any MakerSpace, is the 3-D printer. Certainly, the highest quality 3-D printers on the market are incredibly expensive, but the ones used in the Stephenson Lab are actually only $750 per printer. Even better, most spools of the PLA filaments used in printers like this one can be found online for under a price of $30 each. With access to free CAD-modeling services like OpenScad and SketchUp, all you need is a computer to start 3-D printing on your own.

But if you can’t afford a 3-D printer, or want to add more electric components to the plastic designs the printer can make, the Stephenson Lab also has NI myDAQ devices, external power sources, wires, resistors, voltage meters, Arduino kits, and other equipment that can all be purchased by students for less than $500.

The most expensive device is the NI myDAQ, which costs $200 for students, but $400 for everyone else. With access to software that includes a digital multimeter, oscilloscope, function generator, Bode analyzer, and several other applications, the myDAQ is essential to any project that involves data with electronic signals. But even without the myDAQ, components like breadboards, wire cutters, resistors, voltage regulators, and all of the other basic elements of circuitry can typically be found online for a total price of under $100.

The Stephenson Lab also provides students with Arduino Kits, which are a combination of hardware and software in circuitry and programming that can be purchased for under $100 from the Arduino website. With sensors, breadboards, and other essential circuit elements, the Arduino Kits also allow users to control their designs through a software code that corresponds to hands-on setup. Particularly for those new to understanding the relationship between codes and circuitry, an Arduino Kit can be a great place to start.

Using all of these items, you can easily start your own MakerSpace for under $1500, especially if you can take advantage of student pricing. At the heart of the MakerSpace movement is the notion that anyone, anywhere can bring their own ideas and innovations to reality with the right equipment. So if you have a project in mind, get started on building your own MakerSpace, with these tools or your own — it’s cheaper than you’d think!

As technology and hands-on activities continue to become a larger part of education at all levels, a new movement of do-it-yourself projects is on the rise. Known as the “MakerSpace Movement,” the idea is that with the use of devices like 3-D printers, laser cutters, and simple circuitry materials, students, classes and communities can apply topics discussed in the classroom to real-life projects. Especially popular among STEM educators, the MakerSpace Movement is one that’s taken over labs in engineering schools around the country. Here at Penn, our own

As technology and hands-on activities continue to become a larger part of education at all levels, a new movement of do-it-yourself projects is on the rise. Known as the “MakerSpace Movement,” the idea is that with the use of devices like 3-D printers, laser cutters, and simple circuitry materials, students, classes and communities can apply topics discussed in the classroom to real-life projects. Especially popular among STEM educators, the MakerSpace Movement is one that’s taken over labs in engineering schools around the country. Here at Penn, our own  Believe it or not, however, some of the best parts of the Bio-MakerSpace can actually be purchased for a total of under $1500. Though that number is probably far beyond the individual budget of most students, it might be more affordable for a student club or dorm floor that receives additional funding from Penn. While the idea of building a MakerSpace from nothing might sound intimidating, the popularity of the movement actually helps to provide a wide range of technology and affordable options.

Believe it or not, however, some of the best parts of the Bio-MakerSpace can actually be purchased for a total of under $1500. Though that number is probably far beyond the individual budget of most students, it might be more affordable for a student club or dorm floor that receives additional funding from Penn. While the idea of building a MakerSpace from nothing might sound intimidating, the popularity of the movement actually helps to provide a wide range of technology and affordable options.

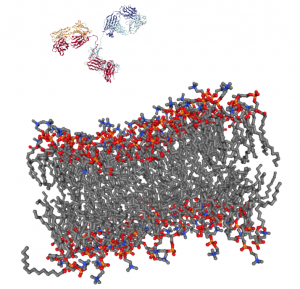

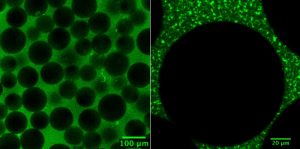

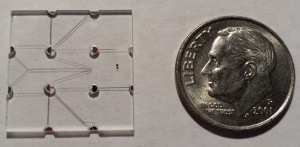

In the last 20 years, microfabrication techniques have allowed researchers to miniaturize tools for a plethora of bioanalytical applications. In addition to better sensitivity, accuracy and precision, scaling down the size of bioanalytical tools has led to the exploitation of new technologies to further manipulate biomolecules in ways that has never before been achieved. For example, when microfluidic channels are on the same order of magnitude of the electric double layers that form due to localized charge at the surfaces, there exists unique physics that create different flow phenomenon, such as analyte concentration and/or separation, mainly due to the couples physics of electrostatics and fluid dynamics. This talk will outline the basis of such interesting phenomena, such as nanofluidic separation and concentration, and well as probe the applications of such coupled systems, for example, handheld DNA detection. Most importantly, we will focus on the most recent work in the Pennathur lab in this field — biopolar electrode (BPE)-based phenomenon. Bipolar electrodes (BPE) have been studied in microfluidic systems over the past few decades, and through rigorous experimentally-validated modeling of the rich combined physics of fluid dynamics, electrokinetics, and electrochemistry at BPEs, I will show the potential of utilizing microfluidic-based BPEs for the design and development of low power, accurate, low volume fluid pumping mechanisms, with the ultimate goal of integration into wearable drug delivery and µTAS systems.

In the last 20 years, microfabrication techniques have allowed researchers to miniaturize tools for a plethora of bioanalytical applications. In addition to better sensitivity, accuracy and precision, scaling down the size of bioanalytical tools has led to the exploitation of new technologies to further manipulate biomolecules in ways that has never before been achieved. For example, when microfluidic channels are on the same order of magnitude of the electric double layers that form due to localized charge at the surfaces, there exists unique physics that create different flow phenomenon, such as analyte concentration and/or separation, mainly due to the couples physics of electrostatics and fluid dynamics. This talk will outline the basis of such interesting phenomena, such as nanofluidic separation and concentration, and well as probe the applications of such coupled systems, for example, handheld DNA detection. Most importantly, we will focus on the most recent work in the Pennathur lab in this field — biopolar electrode (BPE)-based phenomenon. Bipolar electrodes (BPE) have been studied in microfluidic systems over the past few decades, and through rigorous experimentally-validated modeling of the rich combined physics of fluid dynamics, electrokinetics, and electrochemistry at BPEs, I will show the potential of utilizing microfluidic-based BPEs for the design and development of low power, accurate, low volume fluid pumping mechanisms, with the ultimate goal of integration into wearable drug delivery and µTAS systems.