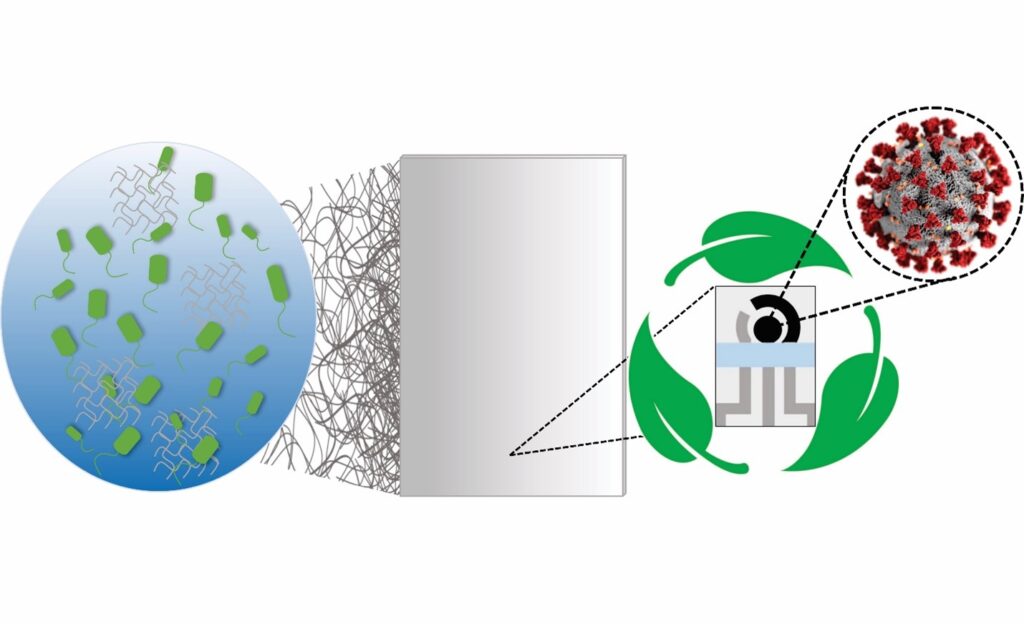

Following the global COVID-19 pandemic, the development and rapid deployment of mRNA vaccines highlighted the critical role of lipid nanoparticles (LNPs) in the context of pharmaceuticals. Used as the essential delivery vehicles for fragile RNA-based therapies and vaccines, LNPs protect the RNA from degradation and ensure effective delivery within the body.

Despite their critical importance, the large-scale manufacturing of these LNPs saw numerous bottlenecks during the pandemic, underscoring the need for scalable production techniques that could keep pace with global demand.

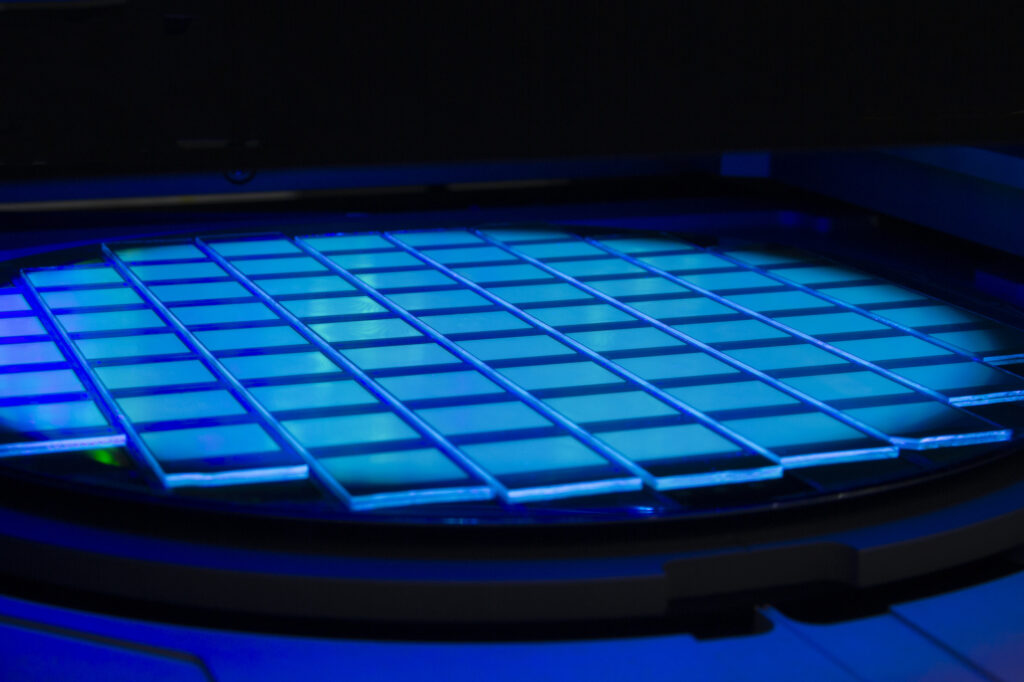

Now, in a paper published in the Proceedings of the National Academy of the Sciences, researchers at the University of Pennsylvania describe how the Silicon Scalable Lipid Nanoparticle Generation platform (SCALAR), a reusable silicon- and glass-based platform designed to transform the production landscape of LNPs for RNA therapeutics and vaccines, offers a scalable and efficient solution to the challenges exposed during the COVID-19 crisis.

“We’re excited to create a piece of technology platform that bridges the gap between small-scale discovery and large-scale manufacturing in the realm of RNA lipid nanoparticle vaccines and therapeutics,” says co-author Michael Mitchell, associate professor of bioengineering in the School of Engineering and Applied Science at Penn. “By doing so, we’ve effectively leapfrogged the clunky, time-consuming, and costly barriers that slow down the production ramp-up of promising new RNA medicines and vaccines.”

The intricacies of RNA-based therapies require the RNA to be encased in a delivery system capable of navigating the body’s biological obstacles. LNPs fulfill this role, allowing the RNA to reach the intended cells for maximum therapeutic impact. SCALAR aims to take this a step further, allowing for an unprecedented three orders of magnitude scalability in LNP production rates, addressing the speed and consistency bottlenecks that hinder existing methods.

Sarah Shepherd, the first author of the paper and a recent Ph.D. graduate who worked in the Mitchell Lab, says, “With SCALAR, we’re not just reacting to today’s challenges but proactively preparing for tomorrow’s opportunities and crises. This technology is flexible, uses mixing architectures well-documented in microfluidics, and is scalable enough to meet future demands in real time. That’s an enormous leap forward for the field.”

Shepherd says that SCALAR builds on prior work from the Mitchell lab and is based on a microfluidic chip platform. Akin to a computer chip, wherein a computer’s electrically integrated circuit has numerous little transistors transporting signals as ones or zeroes to produce an output, the SCALAR microchip precisely controls their two key reagents, lipids and RNA, to generate LNPs.

Read the full story in Penn Today.

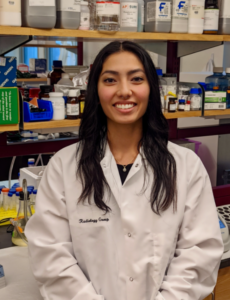

Cosette Tomita, a master’s student in Bioengineering, spoke with Penn Engineering Graduate Admissions about her research in cellular therapy and her path to Penn Engineering.

Cosette Tomita, a master’s student in Bioengineering, spoke with Penn Engineering Graduate Admissions about her research in cellular therapy and her path to Penn Engineering.

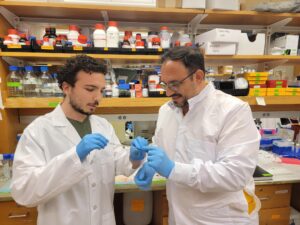

A research team led by engineers at the

A research team led by engineers at the