by Sophie Burkholder

Almost every engineering school in the country offers a course in mechatronics — the overlap of mechanical, electrical, and computer engineering in electromechanical system design — but how many offer a course in biomechatronics? Taught by LeAnn Dourte, Ph.D., a Practice Associate Professor in Bioengineering, Penn Engineering’s Biomechatronics course (BE 570) gives students the chance to think about how the principles of mechatronic design can be used in biological settings involving orthopaedics, cardiovascular systems, and respiration, to name a few.

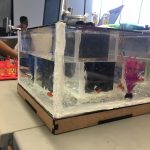

Throughout the course, students engage in different projects related to circuitry, signal processing, mechanics, motors, and analog controls, eventually applying all of these to biological examples before working on a final culminating project in design teams of two. In a simulation meant to mimic the sort of thinking and design processes that go behind innovations in robotic surgery, students create an electromechanical device that acts as a robotic hand. The catch? The “hand” has to have enough dexterity to pick up a water bead with a slipperiness similar to that of human tissue.

In addition to successfully performing this mechanical task using skills that the students learned throughout the semester, design teams also have to incorporate biological interfaces into the final project, such as using EMG signals to move part of the robotic hand, to give one example. Furthermore, each team needs to have a unique element to their design, whether in the use of a second biological interface, the application of Bluetooth to the system, or even a physical extension of the robotic hand to include the electromechanical equivalents of a shoulder, elbow, or wrist joint.

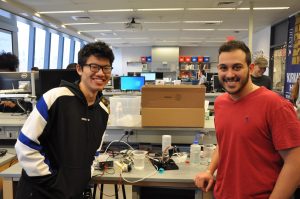

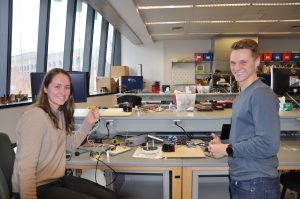

Students Carolyn Godone and Mike Furr (both M.S.E. in Bioengineering ‘19) created a design inspired by the mechanical iris of a camera lens, using gears to push 3-D printed slices together in a symmetrical pattern to close around an object for pickup. They controlled their unique gripper with a thermal sensing camera that could employ a heat map of the device’s user to rotate, raise, and lower the gripper. Another pair of students, Omar Abdoun (BE M.D./Ph.D. student) and Andrew Chan (M.S.E. in Robotics ‘19), made what they called a “cryogripper”: a tissue moistened with water that freezes on demand when it contacts its target hydrogel. The ice allows the target to be lifted without falling, and the tissue can later be thawed with pumps of warm water to release hydrogel.

After weeks of working on their projects in the George H. Stephenson Foundation Educational Laboratory and Bio-MakerSpace, the class presented their final robotic hands during an open demonstration day (or Demo Day) in the lab. To see all the devices live and in action, watch the Facebook video below!

The

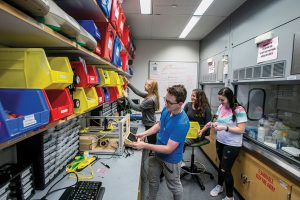

The  As technology and hands-on activities continue to become a larger part of education at all levels, a new movement of do-it-yourself projects is on the rise. Known as the “MakerSpace Movement,” the idea is that with the use of devices like 3-D printers, laser cutters, and simple circuitry materials, students, classes and communities can apply topics discussed in the classroom to real-life projects. Especially popular among STEM educators, the MakerSpace Movement is one that’s taken over labs in engineering schools around the country. Here at Penn, our own

As technology and hands-on activities continue to become a larger part of education at all levels, a new movement of do-it-yourself projects is on the rise. Known as the “MakerSpace Movement,” the idea is that with the use of devices like 3-D printers, laser cutters, and simple circuitry materials, students, classes and communities can apply topics discussed in the classroom to real-life projects. Especially popular among STEM educators, the MakerSpace Movement is one that’s taken over labs in engineering schools around the country. Here at Penn, our own  Believe it or not, however, some of the best parts of the Bio-MakerSpace can actually be purchased for a total of under $1500. Though that number is probably far beyond the individual budget of most students, it might be more affordable for a student club or dorm floor that receives additional funding from Penn. While the idea of building a MakerSpace from nothing might sound intimidating, the popularity of the movement actually helps to provide a wide range of technology and affordable options.

Believe it or not, however, some of the best parts of the Bio-MakerSpace can actually be purchased for a total of under $1500. Though that number is probably far beyond the individual budget of most students, it might be more affordable for a student club or dorm floor that receives additional funding from Penn. While the idea of building a MakerSpace from nothing might sound intimidating, the popularity of the movement actually helps to provide a wide range of technology and affordable options.