The sting of a toothache or the discovery of a cavity is a universal dread. Dental caries, more commonly known as tooth decay, is an insidious adversary, taking a toll on millions of mouths worldwide. Caries can lead to pain, tooth loss, infection, and, in severe cases, even death.

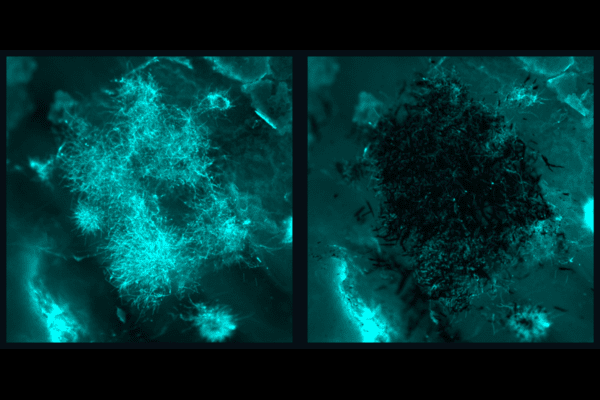

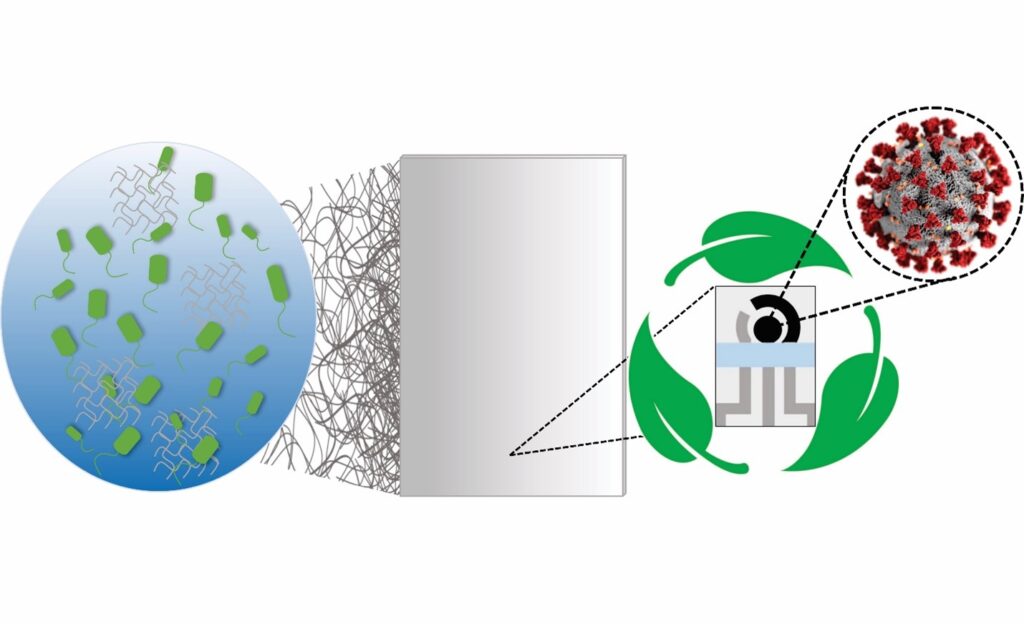

While fluoride-based treatments have long been the gold standard in dentistry, this singular approach is now dated and has limited effect. Current treatments do not sufficiently control biofilm—the main culprit behind dental caries—and prevent enamel demineralization at the same time. This dual dilemma becomes particularly pronounced in high-risk populations where the onset of the disease can be both rapid and severe.

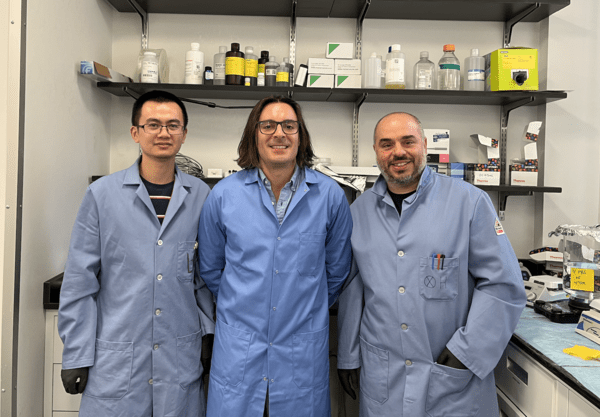

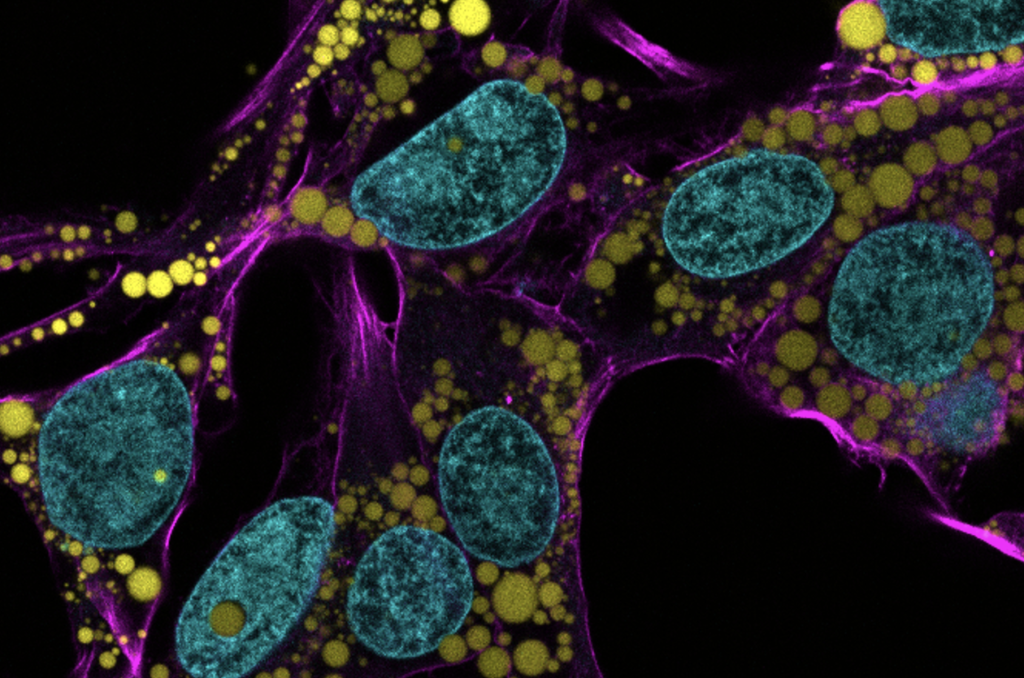

Now, a study from a team of researchers led by Hyun (Michel) Koo of the University of Pennsylvania’s School of Dental Medicine in collaboration with David Cormode of Penn’s Perelman School of Medicine and School of Engineering and Applied Science has unveiled an unexpected synergy in the battle against dental caries. Their research revealed that the combination of ferumoxytol (Fer) and stannous fluoride (SnF2) could point at a potent solution against dental caries. Their findings were published in Nature Communications.

“Traditional treatments often come short in managing the complex biofilm environment in the mouth,” Koo, senior co-author on the study, says. “Our combined treatment not only amplifies the effectiveness of each agent but does so with a lower dosage, hinting at a potentially revolutionary method for caries prevention in high-risk individuals.”

Read the full story in Penn Today.

Hyun (Michel) Koo is a professor in the Department of Orthodontics and in the divisions of Pediatric Dentistry and Community Oral Health and the co-founder of the Center for Innovation & Precision Dentistry in the School of Dental Medicine at the University of Pennsylvania. He is a member of the Penn Bioengineering Graduate Group.

David Cormode is an associate professor of radiology and bioengineering with appointments in Penn’s Perelman School of Medicine and School of Engineering and Applied Science.

Other authors are Yue Huang, Nil Kanatha Pandey, Shrey Shah, and Jessica C. Hsu of Penn’s Perelman School of Medicine; Yuan Liu, Aurea Simon-Soro, Zhi Ren, Zhenting Xiaang, Dongyeop Kim, Tatsuro Ito, Min Jun Oh, and Yong Li of Penn’s School of Dental Medicine; Paul. J Smeets, Sarah Boyer, Xingchen Zhao, and Derk Joester of Northwestern University; and Domenick T. Zero of Indiana University.

The work was supported by the National Institute of Health (grants R01-DE025848 and TL1TR001423 and awards S10OD026871 and R90DE031532) and the National Science Foundation (awards ECCS-2025633 and DMR-1720139).